Reversible tote bags. I’ve been loving making these, but I had never taken the time to create a tutorial or take enough pictures for a tutorial. The last bag I made was for a sister of mine, and I finally took enough pictures to write up a tutorial!

This particular tote differs from the others I have made in a few ways. First, I used fat quarters to piece the exterior shell, rather than one solid piece of fabric. Second, I decided to try using pre-made purse handles. I was using a drastically different fabric for the interior shell (purple), which meant finding fabric to create straps that coordinated with both colors was nearly impossible. This project was my first using pre-made purse straps, and I kind of want to go back to my other bags and replace the straps!

Supplies

4 fat quarters for outer shell

~ 2/3 yard fabric for inner shell

~ 1/4 yard fabric for inner pocket

~3 yards fusible heavy craft-weight interfacing

3/4 yard cotton netting

1 set pre-made bag handles

Sewing machine

Iron

Pins

Coordinating thread

Ruler

Rotary cutter

Seam ripper

Fabric marking pen

Heavy-weight needle (110/20 is what I used)

Cutting the Fabric

From the fat quarters:

* 2 pieces 6″x 18″ from Fat Quarter 1 (topmost fabric)

* 2 pieces 6″x 18″ from Fat Quarter 2 (middle fabric)

* 2 pieces 8″x 18″ from Fat Quarter 3 (bottom of the bag)

* 2 pieces 6″x 6″ from Fat quarter 4 (pocket)

From the other fabric:

* 2 pieces 17″ x 20″ (inner shell)

* 2 pieces 6″ x 6″ (other pocket)

From the interfacing:

* 4 pieces 17″ x 20″

* 4 pieces 6″ x 6″

From the netting:

* 4, 5″-6″ lengths (depends on how far up from the bag you want the rings to be)

Bag Handles

Using your lengths of netting, simply thread each through the metal ring and sew the loose ends closed.

|

| One length of the netting I used. |

|

| All rings except one have the netting attached. |

|

| Close-up of the finished netting on the rings. |

Assembling the Bag Pieces

Simply sew the three different fabrics for the outer shell together along the 18″ side, using a 1/4″ seam allowance.

Iron your seams flat (can be open or pressed to the darker fabric).

|

| The pieces of the outer shell for one side of the bag. |

|

| Interfacing, outer shell… and my toes. |

Attach the interfacing pieces to each large rectangle for both the outer and inner shells. You should have 4 large rectangles of interfaced fabric. In this bag, I actually didn’t interface the inner shell, and it still came out as a pretty sturdy bag. So, depending on how much wear and tear you think both shells are going to take, you might want to use interfacing on both shells.

Attach the interfacing to the pocket pieces, as well. These take interfacing on both pieces of each pocket to make for a very study pocket.

|

| Pocket piece for the outer shell of the bag. |

For the pockets: with fabric right sides together, sew around the 4 sides, leaving a gap for turning the pocket inside-out. If you’re using directional fabric, MAKE SURE the opening is on the bottom of the pocket. This way, when you stitch the pocket onto the bag, you will also be closing the seam. Turn the pockets inside out so the fabric is now facing out in both front and back. Press the gap so that the fabric and interfacing are tucked inside, so that when you look at the pocket, it seems like it’s completely sewn shut. (I apologize for the lack of photos for these steps!)

Center outer shell pocket on one outer shell rectangle, and do the same for the inner shell pocket. I found that I don’t actually need to leave too much give on the pockets to have enough room for whatever I plan on storing inside. Pin the pockets in place. At the sewing machine, start on the right side of the pocket, stay stitch a few times before going down the right side. At the bottom right corner, stay-stitch, then rotate the fabric to stitch across the bottom; stay-stitch the left bottom corner, then stitch up the left side, stay-stitching at the top left corner of the pocket. The stay-stitching will help reinforce the weak points of the pockets.

Do the same for the inner shell.

|

| Outer shell with pocket attached and a pit of interfacing peaking out the bottom. |

Now, place the two outer shell pieces together, right-sides together, and stitch down the right, bottom, and left sides of the bag. Do the same with the inner shell pieces. Use a 1/4″ seam allowance. Trim any excess fabric or interfacing.

|

| The inner shell sewn together. |

|

| Ta-da! Inner shell. |

Next, attach the handles to the inner shell. Judge how far apart you want the base of the handles to be. I attached mine about 4″ from the outer edge. (NOTE: Upon reviewing this, I realized I should have waited to attach the bag handles because sewing through 4 thicknesses of netting PLUS the bag fabrics was really tough to do. You can wait until assembling the shells together to attach the bag handles. In fact, I highly recommend doing so.)

|

| Handles about to be attached to the inner shell. I wish I had waited to do this step. |

Boxing Corners

Next, we’re going to box the corners for both shells. This can be tricky to explain.

At one bottom corner, pinch the fabric so that the side seam and the bottom seam are touching. This will create a triangle.

|

| Pinching the corner together. |

|

| Another view of the corner being pinched together. See how the bottom seam and side seam are lining up? |

Next, measure 3″ from the corner seam and draw a line. NOTE: Your shells should still be right-sides together during this. Sew along the line you drew, stay-stitching at the both ends of the stitching. Do the same on the other corner. Pay special attention that your bottom seam doesn’t end up twisting as you create the second boxed corner.

|

| Sorry for the blurriness. Measuring from the seam for boxing the corners on the inner shell. |

|

| Sewing along the line I drew to create the boxed corner. |

Don’t trim the excess; I like that it can help reinforce those corners of the bag.

Putting the Shells Together

Pull the inner shell so that it’s right-side out. Tuck this shell into the outer shell so that the fabric sides of both shells are touching. Tuck the handles into the space between the two shells. (As I reviewed this part, I realized I could have skipped attaching the handles to the inner shell and pinned them in between the two shells at this point. It would have saved me from having 4 thicknesses of netting to sew through, which was rather difficult!!)

NOTE: Be sure the pockets are on opposite sides from each other. This will help distribute the weight of the items in the pockets.

Match the side seams together and pin those together. You may want to pin around the entire top of the bag, leaving a 4″ or 5″ gap for turning the bag right sides out. I usually don’t because I’m lazy, and I usually find myself wishing I had as I get to the side seams which have inevitably shifted just a smidge.

Stitch around the top of the bag, leaving that gap unstitched, else you’ll have yourself a wonderful, inside-out bag with no handles (trust me, I’ve done it). Stay-stitch on each end of the gap so that pulling the outer shell fabric doesn’t tear your seam (and bag) too much. I like the leave the gap on one of the side seams.

If you’ve wisely wait until now to attach the bag handles, you may have a bit of netting sticking out from between the bag sides. Don’t worry – this will be safely tucked inside when all is said and done.

|

| Tucking the bag handles inside the bag. |

|

| Stitching through all those layers of netting. Not fun. |

|

| Leaving a gap to turn the bag out. |

|

| See that gap? It’s really handy and necessary. |

Finishing

Pull the outer shell and the handles out through the gap you left.

|

| Mid-pulling the outer shell through the opening. |

|

| This is what the bag looks like before stuffing the inner shell into the outer shell. |

Tuck the inner shell into the outer shell. Press the tops, tucking the folds of the gap so that when you top-stitch around the bag, it will sew that gap closed.

|

| Inner shell tucked into the outer shell. |

Then, simply top-stitch around the top of the bag, close to the edge, sewing the opening you pulled the bag through closed in the process.

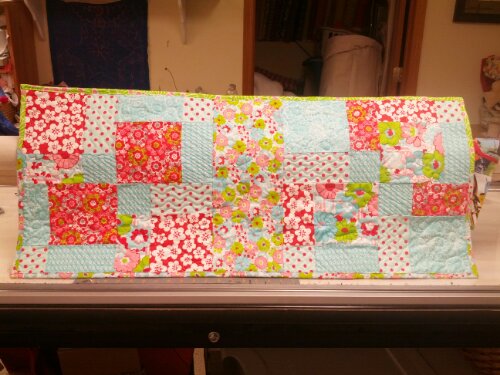

|

| Inner shell tucked into the outer shell. Gap still needs to be sewn shut, but I LOVED the look of the outer shell. |

Sadly, I forgot to take a photo of the finished bag when it was completely finished. The above photo is as close as it gets to the finished product (but it’s really close!).

Happy bag-making!